Ky-25n Automatic Vffs Roll Filling Dry Yeast Powder Vacuum Packing Machine Vacuuming Sealer for Food Three Side Seal /Four Side Seal Bag

Description

Basic Info

| Model NO. | ky-25n |

| Application | Food, Rice,Beans,Grains,Seeds,Nuts,Coffee,Tea,Feed |

| Power | Mechanical |

| Automation | Automatic |

| Inflatable Device | Without Inflatable Device |

| Type | Automatic Bag Vacuum Packing Machine |

| Object State | Solid |

| Condition | New |

| Packing Range | 0.25-5kg |

| Bag Type | Brick Bag,Pillow Bag |

| Dosying System | Linear Weigher |

| Packing Speed | 700~800bags/Hour |

| Accuracy | ±0.2% |

| Transport Package | Export Standard Wooden Cases |

| Specification | 2100x1600x3800mm |

| Trademark | Koyo |

| Origin | Hefei, China |

| HS Code | 8422303090 |

| Production Capacity | 50000 Sets/Year |

Product Description

Product Introduction :

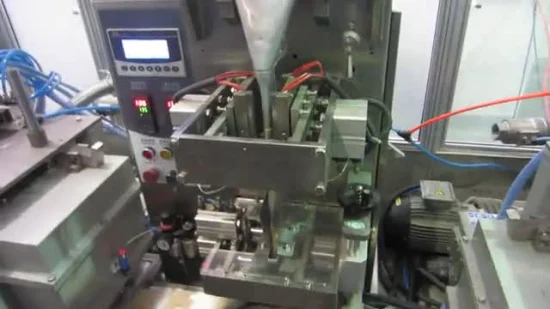

1)KY-25N vacuum packaging machine unit is one of our newest products which is suitable for vacuum packing granule material(beans, rice, etc.) and powder material( coffee powder, yeast ,etc.) It's hot sell because of its high speed.

2)All of the vacuum line is covered by aluminium alloy and organic glass.

3)The whole line is consist of one set of weighing packing machine,one conveyor which can convey bags to the opposite directions and two sets of automatic vacuum chambers.

4)Most of the electric and pneumatic components adopts international brands, like OMRON, SIEMENS,SMC,etc.

| 1. Equipped with automatic bagging manipulator to realize automatic vacuum shaping packaging, weighing, bagging, six-sided |

| 2. The whole process of shaping, vacuuming, heat sealing, unloading, and finished product conveying is controlled automatically. |

| 3.Double-station bagging, double-station vacuum shaping design, rotating and vertical delivery mechanism, vacuum packaging working speed is fast. |

| 4. The wide-capacity shaping mechanism is suitable for thick and thin shape packaging, with good shaping effect and large packaging range. |

| 5.It adopts high-precision alloy steel sensor, pneumatic and vibration feeding mechanism, fast weighing speed and high packaging accuracy. |

| 6.Using Chinese display touch screen, Siemens programmable controller, touch screen intelligent weighing module. |

Machine working progress:Material is automatic weighed and packed by the KY-F50 packing machine,seal and pack every 5-continue bags once ------the conveyor convey 5-continue bags to one side of vacuum chamber, 5bags vacuum,reseal,cut inside of the chamber automatically,then convey out-------another 5-continue bags conveyed to the other chamber at the other side. Machine Parameters:Bag type: 4 side seal 5-continue vacuum bag;Packaging weight: 20g-50gPacking Speed:35-40bags/minPower: AC 380V,50Hz, 15.2kw

| 1.Who we are? |

| We are manufacturer of automatic weighing packing machines , located in Hefei city,Anhui province,China.We were founded in 1998, already engaged in this packaging field more than 20 years. |

| 2.What we are producing and selling? |

| Our products mainly includes automatic vertical weighing packing machines,automatic vacuum packing machine,automatic filling line,automatic bulk packaging& palletizing line, automatic secondary packing line for baler bags in plastic bag / pp woven bag/carton and ancillary equipment. |

| 3.Do we have our own production R&D team? Yes,We have professional teams for machine design,drawing making,machine assembling and testing,we also have a professional service team who can go abroad to help customer install and test the machines,also giving training. |

| 4.Do we have experience in non-standard design? |

| Yes, we have designed and made some non-standard design packaging lines for customers, such as the screw weigher for ice cubes, which greatly reduces the problem of ice agglomeration We designed and developed bag edge folding & sealing and bottom flatting device on packing machine to make more beautiful bag shapes.We developed a high speed continuous packaging machine for increasing the packaging speed to 100bags per min.We developed a lifting screw metering machine to solve the dust problem in the ultra fine powder packaging process,etc. |

| 5.What certifications have our products passed? |

| Our products have passed ISO9001:2008 and CE certificates. |

| 6.How to pack our machines? |

| After the machine is cleaned up, it is wrapped with film first, and then packaged in a wooden export box. |

| 7.What after-sales service can we provide? |

| 7.1we can communicate with shipping agent and delivery machine for customer; 7.2we will offer customer the user manual,electrical diagram,installation video,etc. 7.3we will offer customer documents for clean custom,includes commercial invoice,packing list, bill of lading, certificate of origin,etc. 7.4 we will answer questions online from customer any time. 7.5we can send engineer to abroad for helping customer install & test machines and training. 7.6In the case of non-man-made damage, we will express the accessories free of charge and let the customer replace it. If it is deemed damaged, we only charge the cost price for the spare parts. |

| 8.Which countries are our products sold to? |

| Vietnam, Indonesia, Thailand, Malaysia, Cambodia, Singapore, South Korea, Japan, Colombia, Peru, Uzbekistan, Russia, Egypt, Syria, Iran, United States, etc. |

Our Contact